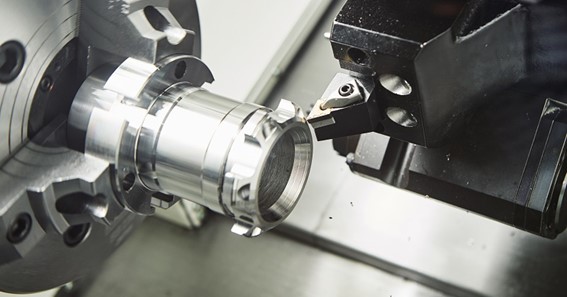

From an economic perspective, nothing can beat CNC Machining technology, when it comes to on-demand manufacturing of metal parts, even with the existence of newer fabrication methods. Whether you are looking to fabricate components for prototyping, or replacement parts, tooling, molds, and customized parts, it might be best for you to opt for CNC machining services. CNC Machining is an established method for fabricating that can be dated back to the 1980s and has been further developed ever since.

Why should choose CNC Machining Services?

CNC Machining has existed for a long time, and it has been one of the most reliable and established fabrication methods. The parts created through CNC can be very complex but still have the highest degree of precision and accuracy.

In addition, if your parts need to be strong, then CNC machining is the right one for your prototype. Machined parts are very reliable in many aspects. And because they are machined from a block of material, these parts retain their strength and structural integrity, wherein they will be free from any troubles concerning material porosity, delamination, and part warpage adamant in other fabrication methods.

The failure to fabricate a part through CNC machining is very slim given that the tools, parameters, and other factors are set the right way. For this reason, this fabrication method is dominant in producing highly critical components for the aerospace, automotive, and medical industry.

click here – How Manifestation Journal Can Help With Your Goals

A wide range of Metal Raw Materials can be used

One advantage of CNC fabrication is that you get to choose a raw material to work on from wide availability of machinable metals available. Unlike additive manufacturing, where materials are limited, simply because 3D printing is a relatively newer fabrication method and few materials are established for it.

Visit here to know about machinist tools for sale.

This may come in handy when your material requires specific mechanical properties to adjust and match your application. For example, when you need a high-strength part with lightweight characteristics, you need a strong part that should be corrosion resistant or need a high-strength part that should not be magnetic and other similar scenarios.

Scalable Production

CNC machining services are definitely scalable to any volume of production, from low volume to high volume. CNC machining can produce any part “as-demanded.” It also has the ability to mass-produce precision parts uniformly. One thing to note about this is the unit price for machining a product greatly reduces as the volume increases, like almost any method.

click here – Which filter is the best for drinking water?

Different Applications of CNC Machining Services

CNC machining is one of the most versatile fabrication methods due to its broad range of applications in different walks of life, ranging from basic utilities to complex structures and small scale to large scale production.

1. Manufacturing industry

One of the major users of machined metal parts is the manufacturing and fabrication industries, where custom-designed parts are required to produce units successfully. These parts come in many forms, and some of these are:

- Assembly Jigs- Enables a fast and efficient movement of production parts in the assembly line.

- Tooling Die and Molds- machined metal parts are used for the forming types of fabrication like injection molding, forging, die casting, and roll forming.

- Machining Fixtures- fabricators also utilize these parts to aid in the process of machining where there might be constraints for the machine. Some of these parts include soft jaws, work-holding fixtures, maskings, and many more.

2. Automotive industry

CNC machining is very useful in the automotive industry, whether for creating prototypes or actual parts. In fact, most of the parts we see on an automotive system have undergone CNC machining in some way. These include parts like engine blocks, manifolds, crankshafts, pistons, valves, cylinders, and even parts like the dashboard panels, car letterings, and rims. And because low-scale production is allowable in CNC machining, custom-designed components can be made (e.g., replacement parts, customized car designs, and other bespoke parts).

3. Aerospace Industry

This industry has the toughest demand when it comes to the quality of precision, accuracy, and strength. Aerospace parts can be very small or very large and still very accurate at tight tolerances. Indeed, CNC machining is the most reliable way of achieving these requirements for parts. Some machined parts in an aircraft include engine block, flight control manifolds, actuator components, gears, landing system components, turbines, and many more.

4. Medical Industry

In the medical industry, all of the equipment and other parts are required to have a very high factor of safety due to its critical implication for humans. Machined parts in the medical industry may vary from parts used on pieces of machinery (e.g., ventilators, scanners, etc.) to parts used for prosthetics and metal implants. These parts should be very accurate and, most of all, non-corrosive.

5. Product Development

One of the increasing markets for CNC machining services are parts used for rapid prototyping and development needs because this can cater for on-demand production even with low volumes.

6. Consumer electronics

The main use for CNC machined parts in the consumer electronics sector are enclosures and chassis. Machined parts provide exceptional protection for devices such as laptops, cellphones, and other electronic appliances.

7. Robotics and Automation

Robotics is a combination of electronics and mechanical engineering wherein the computing system’s commands are executed physically through the mechanical components. The mechanical components used in robotics and automation are created and fabricated through CNC machining services.

How To Choose The Best CNC Machining Services Provider

-

Topnotch Quality & Excellent Workmanship Standards

Make sure to entrust your parts to a machine shop that has done parts with exceptional quality and accuracy. Assess a potential service provider through their customer feedback and reviews as well as their portfolio of past projects. This will assure you that they have best practices within their processes.

-

Trusted and Established Facility

Choose a service provider with an established name in the industry that clients have trusted for a long time.

Look for a trusted machine shop that will not just produce your products but also extend their help and customer service to guide you through the process, from design, machining, and finally to the finished product.

-

Wide Availability of CNC Machines and Additional services

One thing to look for in choosing the best facility is to look for the one with a wide availability of machining processes (e.g., multi-axis milling, EDM processes, turning, grinding, and other finishing equipment). This will help you be assured of their flexibility to whatever requirements and specifications you have for your part.

Conclusion

CNC Machining has existed for a long time, and it has been one of the most reliable and established fabrication methods. You need CNC Machining services when you are looking to fabricate custom metal parts that have high precision, accuracy, and strength. CNC machining can serve you from all walks of life in many industries. Suppose you have decided that you need it now, then you should choose a provider that has topnotch quality & excellent workmanship standards, a trusted and established facility, and wide availability of CNC machines and additional services.