The key factor restricting the development of electric vehicles is that the power battery is not ideal. The main performance indicators of electric vehicle batteries are specific energy, specific power, and service life. To make electric vehicles compete with internal combustion engine vehicles, the key is to develop batteries with high specific energy, high specific power, long service life, and low cost. (Specific energy, electronic term, the size of the electrical energy released by the unit mass of the electrode material participating in the electrode reaction, is called the specific energy of the battery.) The device that converts chemical energy into electrical energy is called a chemical battery, generally referred to as a battery. After discharge, the internal active material can be regenerated by charging – storing electrical energy as chemical energy; when it needs to be discharged, the chemical energy can be converted into electrical energy again. This type of battery(12v, 24v battery or 48v battery) is called a storage battery, also called a secondary battery.

-

Lead-acid batteries

Working principle of lead-acid battery: When charging, the internal active material is regenerated using external electric energy, and the electric energy is stored as chemical energy. It uses a lead substrate grid filled with spongy lead (also known as a lattice) as a negative electrode, a lead substrate grid filled with lead dioxide as a positive electrode, and dilute sulfuric acid with a density of 1.26–1.33g/ml/ml is used as the electrolyte. When the battery is discharging, metal lead is the negative electrode, which undergoes an oxidation reaction to generate lead sulfate; lead dioxide is the positive electrode, which undergoes a reduction reaction to generate lead sulfate. When the battery is charged with direct current, elemental lead and lead dioxide are formed at the two poles, respectively. When the power source is removed, it returns to its pre-discharge state, forming a chemical battery.

click here – Purchase Wigs Online To Buy The Best Styles And Color

Application:

Backup power

- Telecommunication, solar powered generator system, electronic switch system, etc.

- Communication equipment (base station, PBX, CATV, WLL, ONU, STB, cordless phone, etc.)

- Backup power supply (UPS, ECR, computer backup system, etc.)

- Emergency equipment (emergency lights, flashlights, fire burglar alarms, fire dampers, etc.)

Main power

- Communication equipment (transceiver)

- Electric-controlled locomotives (collection vehicles, automatic transport vehicles, electric wheelchairs, cleaning robots, electric vehicles, etc.)

- Mechanical tool starter (lawn mower, hedge trimmer, cordless drill, electric screwdriver, electric sled, etc.)

- Industrial equipment/instruments

- Camera (flash, VTR/VCR, movie lights, etc.)

- Other portable equipment, etc.

Lead-acid batteries have more than 100 years of history and are widely used as starting power sources for internal combustion engine vehicles.

click here – Vending Machines – Your One Stop Shop?

-

VRLA battery

Although this kind of battery is also a lead-acid battery, it has many advantages compared with the original lead-acid battery. It is very popular with users, especially those who need to install battery-supporting equipment together (or in a workshop). , such as UPS, telecommunications equipment, mobile communication equipment, computers, motorcycles, etc. The basic feature is that there is no need to add acid and water for maintenance during use. The battery is a sealed structure that will not leak or discharge acid mist. A one-way exhaust valve (also called a safety valve) is on the battery cover. The function of this valve is when the amount of gas inside the battery exceeds a certain value (usually expressed by the air pressure value). When the air pressure inside the battery rises to a certain value, the exhaust valve automatically opens to discharge the gas and closes the valve to prevent air from entering the interior.

The difficulty of sealed lead-acid batteries is the electrolysis of water during charging. When the charging reaches a certain voltage (generally above 2.30V/cell), oxygen is released on the battery’s positive electrode, and hydrogen is released on the negative electrode. On the one hand, the released gas releases the acid mist to pollute the environment. On the other hand, the water content in the electrolyte decreases, so it is necessary to add water for maintenance at intervals. Compared with traditional lead-acid batteries, VRLA batteries have the following

advantages:

- Multi-element high-quality grid alloy is used to improve the overpotential of gas release. Standard battery grid alloy releases gas above 2.30V/cell (25°C). After using high-quality multi-component alloys, the gas is released when the temperature is above 2.35V/monomer (25°C), which reduces the amount of gas released.

- Let the negative electrode have excess capacity, 10% more capacity than the positive electrode. In the later stage of charging, the oxygen released by the positive electrode contacts the negative electrode and regenerates water, that is, O2+2Pb→2PbO+2H2SO4→H2O+2PbSO4, so that the negative electrode is in an undercharged state due to the action of oxygen, so no hydrogen is produced. The lead of the negative electrode absorbs the oxygen of the positive electrode, and then it is further converted into water, the so-called cathode absorption.

- To allow the oxygen released by the positive electrode to flow to the negative electrode as soon as possible, a new type of ultra-fine glass fiber separator that is different from the microporous rubber separator used in ordinary lead-acid batteries must be used. The porosity is increased from 50% of the rubber separator to more than 90% so that the oxygen can easily flow to the negative electrode and be converted into water. In addition, the ultra-fine glass fiber separator adsorbs the sulfuric acid electrolyte, so even if the battery is toppled, the electrolyte will not overflow.

- The sealed valve-controlled acid filter structure is adopted so that the acid mist cannot escape achieving the purpose of safety and environmental protection.

Application: Similar to lead-acid batteries

Testing instruments: Midtronics SCP 100 digital battery tester, Midtronics SBT-100 electric vehicle battery tester

-

Nickel (nie4) hydrogen battery

Nickel-metal hydride batteries are alkaline batteries. Nickel-metal hydride batteries have a long cycle life and no memory effect, but they are expensive.

Applications: as large as UPS systems for telecommunication equipment and electric vehicles, as small as power supplies for electric bicycles, lighting equipment, and even beauty tools.

Working principle: The active materials of the positive electrode of the nickel-metal hydride battery are NiOOH (during discharge) and Ni(OH)2 (during charging), and the active materials of the negative plate are H2 (during discharge) and H2O (during charging), and the electrolyte is 30% potassium hydroxide solution. When charging, the negative electrode releases hydrogen gas and stores it in the container, and the positive electrode changes from nickelous hydroxide to nickel hydroxide (NiOOH) and H2O; when discharging, the hydrogen is consumed on the negative electrode, and the positive electrode changes from nickel hydroxide to nickelous hydroxide.

Foreign companies producing nickel-metal hydride batteries for electric vehicles are a joint venture between Ovonie, Toyota, and Panasonic. Ovonie has two unit cells, 80A·h and 130A·h, with a specific energy of 75-80W·h/kg and a cycle life of more than 600 times. Domestically, 55A·h and 100A·h unit cells have been developed, with a specific energy of 65 W·h/kg and a power density of more than 800W/kg.

-

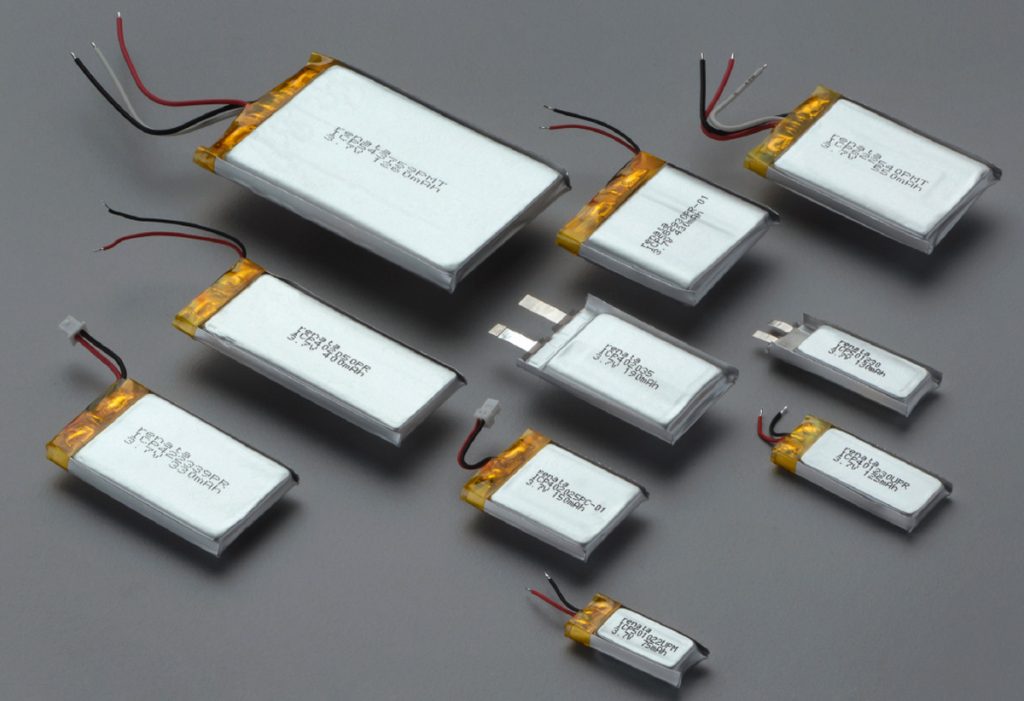

Lithium Ion Battery

Application:

- Portable Electronics

- Music player, video player

- Laptops, tablets, PDAs

- Mobile phone

- Digital camera, a single-lens reflex camera

Electric Vehicle

- Electric straight car, electric bicycle

- New hybrid vehicles (buses), new energy vehicles (used as power sources)

- General purpose vehicles (sedans, passenger cars, commercial vehicles, vans, etc.)

Large power supply

- Large ships (cargo ships, cruise ships, military ships, etc.)

- Aeronautical aircraft (large civil airliner, business aircraft, helicopter, fighter jet, etc.)

- Aerospace power (space shuttles, satellites, rockets, missiles, etc.)

- Armored power (tanks, armored vehicles, large civil excavation equipment, large cranes, etc.)

Secondary charging and energy storage fields

- Electric toys

- Wind energy, solar energy storage power supply

- Power tools (electric drills, grinders, etc.)

- Flashlight

- Electric model aircraft (model airplanes, model ships, model cars, etc.)

Working principle: When the battery is charged, lithium ions are generated on the battery’s positive electrode, and the generated lithium ions move to the negative electrode through the electrolyte. The carbon as the negative electrode has a layered structure and many micropores. The lithium ions reaching the negative electrode are embedded in the micropores of the carbon layer. The more lithium ions are embedded, the higher the charging capacity. Likewise, when the battery is discharged (that is, the process in which we use the battery), the lithium ions embedded in the carbon layer of the negative electrode come out and move back to the positive electrode. The more lithium ions returned to the positive electrode, the higher the discharge capacity.

Lithium-ion secondary batteries, as new high-voltage, high-energy-density rechargeable batteries, have a wide range of prospects for civil and defense applications due to their unique physical and electrochemical properties. Its outstanding features are light weight, large energy storage, no pollution, no memory effect, and long service life. Humans have only developed and utilized 20% to 30% of their theoretical electricity, and the development prospect is very bright. At the same time, it is a real green battery, which will not pollute the environment. It is the current battery that can be applied to electric vehicles. The marine battery is also composed of lithium batteries.

-

Nickel-cadmium batteries

Nickel-cadmium batteries are the earliest types of batteries used in mobile phones and other equipment. They have good high-current discharge characteristics, strong resistance to overcharge and discharge, and simple maintenance.

Application:

- Large bag-type and open-type cadmium-nickel batteries are mainly used for starting or emergency power supply for railway locomotives, mines, armored vehicles, aircraft engines, etc.

- Cylinder-sealed nickel-cadmium batteries are mainly used in portable electrical appliances such as power tools and shavers.

- Small button-type nickel-cadmium batteries are mainly used for cordless phones and electric toys with low current and low rate discharge.

How it works: Cadmium (Cd) in the negative electrode and hydroxide ions (OH-) in a sodium hydroxide (NaOH) are combined to form cadmium hydroxide, which is attached to the anode and also emits electrons. The electrons follow the wire to the cathode, where the nickel dioxide the cathode reacts with water in the sodium hydroxide solution to form nickel hydroxide and hydroxide ions. The nickel hydroxide attaches to the anode, and the hydroxide ions return to hydrogen. In sodium oxide solution, the concentration of sodium hydroxide solution will not decrease with time.

Due to the pollution of waste cadmium nickel batteries to the environment, this series of batteries will gradually be replaced by metal hydride nickel batteries with better performance.

-

Sodium-sulfur battery

A sodium-sulfur battery is a secondary battery with metal sodium as the negative electrode, sulfur as the positive electrode, and a ceramic tube as the electrolyte diaphragm. Under a certain working degree, the sodium ion permeates the reversible reaction between the electrolyte membrane and sulfur, releasing and storing energy. A new type of battery the size of a room, the sodium-sulfur battery, promises to store energy for a huge grid as easily as a reservoir stores water, transforming how electricity is delivered to homes and businesses.

Working principle: General conventional secondary batteries, such as lead-acid batteries, cadmium-nickel batteries, etc., are composed of solid electrodes and liquid electrolytes, while sodium-sulfur batteries are the opposite, which are composed of molten liquid electrodes and solid electrolytes. The active material of the negative electrode is molten metal sodium, and the active material of the positive electrode is sulfur and sodium polysulfide molten salt. Since sulfur is an insulator, sulfur is generally filled in conductive porous carbon or graphite felt. A ceramic material called Al2O3 conducts sodium ions especially, and the outer shell is generally made of metal materials such as stainless steel. Sodium and sulfur will chemically react to store electrical energy. When the grid needs more electrical energy, it will convert chemical energy into electrical energy and release it. The “flood storage” performance of sodium-sulfur batteries is very good, even if the input current It can also withstand a sudden increase of 5-10 times the rated power and then release it into the grid with stable power – which is especially useful for the smooth operation of large urban grids.

Application: Grid power supply. Sodium-sulfur batteries are one of several energy storage technologies that power companies are experimenting with. The traditional form of energy storage is pumped hydro. Since the 1990s, Japanese companies have installed enough sodium-sulfur batteries to light about 155,000 homes, said Brad Roberts, head of the American Electricity Storage Association. American Power supplies 10 percent of the electricity needs of 2,600 customers north of Charleston with sodium-sulfur batteries 15 feet wide and 30 feet high. The battery, which costs about $2.5 million, is charged from the grid at night when electricity demand is low, and prices are low, and it is used to supply electricity during the day when demand is at its peak.

The battery relieves the strain on the grid (especially during the scorching summer months). It has an even more appealing goal of extracting more energy from fast-growing wind farms, solving the problem when wind power is sometimes No problem.

-

Nickel-zinc battery

The nickel-zinc (NiZn) battery is a new type that can replace nickel-metal hydride batteries. Compared with NiMH and NiCd batteries, it has the characteristics of high voltage and strong discharge current. It has unparalleled advantages in digital cameras, flashes, and electric toys.

The capacity of the AA-type nickel-zinc battery is only about 1300mAh, but its discharge energy has reached more than 8300 joules. The difference is not big compared to the current best nickel-metal hydride battery, Eneloop (Ai Lepu, Panasonic). The discharge energy of Eneloop (Ai Lepu, Panasonic) is about 9000 joules. Nickel-zinc batteries have a strong discharge current. Already used in electric vehicles. An AA nickel-zinc battery can release more than 7200 joules of energy at a 2A current discharge. Nickel-zinc batteries are more environmentally friendly. Both nickel and zinc are metals that are recyclable and easy to recycle.

Working principle: The zinc-nickel battery comprises zinc, nickel oxide, potassium hydroxide solution with a mass concentration of 25% to 30%, and a diaphragm. The battery reaction mechanism of Zn/Ni battery:

2Ni(OH)2+Zn(OH)2=2NiOOH+Zn+2H2O

The positive electrode comprises nickel hydroxide, nickel powder, and additives; the negative electrode comprises zinc oxide, zinc powder, and additives.

Applications: digital cameras, flash, electric toys, electric vehicles.

-

Zinc air battery

Zinc-air battery, also known as the zinc-oxygen battery, is a metal-air battery; it uses activated carbon to adsorb oxygen or pure oxygen in the air as the positive active material, zinc as the negative electrode, and ammonium chloride or caustic alkali solution as the electrolyte. Primary battery. The theoretical value of the specific energy of the zinc-air battery is 1350W·h/kg, and the current specific energy has reached 230Wh/kg, almost 8 times that of the lead-acid battery. It can be seen that the development space of zinc-air batteries is very large.

Working principle:

Anode: Zn + 2OH– → ZnO + H2O + 2e–

Cathode: O2 + 2H2O + 4e– → 4OH–

Synthesis: 2Zn + O2→ 2ZnO

Usually, this reaction produces a voltage of 1.4 volts, but the discharge current and depth of discharge can cause voltage variations. Air must be able to enter the cathode uninterrupted, and small holes are opened in the cathode casing to allow the continuous flow of oxygen for the battery’s chemical reaction to occur.

Application: Vehicle power supply, wind, and solar energy storage batteries, off grid solar systems, and military applications.